|

Removed the engine yesterday and hauled it to welding shop in the evening. Welder advised to keep as much parts assembled as possible to minimize warp and to distribute heat more evenly. Relief to us we didn't have to tear engine apart. We did release some tension from the cylinder head bolts! |

|||

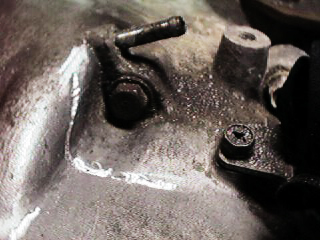

| Blocked turned out to be cracked quite severely. It had two cracks on the top of #1 cylinder. We decided to grind open the cracks for better permeability of weld, not necessary a good thing to do without consulting the welder as it turned out! | |||

| I got a message from my brother at 9:00 AM saying that block had been already welded. Talk about fast action ! He had dropped by at the welding shop to leave something from his Toyota to be welded and at the same time checked the status of Subaru block. Welding specialist told him that it was rather thin wall thickness and thus difficult to weld. Material tended to crack beside the weld seam. I'll post few pics of welded cracks also as i have possibility to snap them. | |||

| I'm planning to test run this engine this evening in out carage to get it warm and circulate water residue out of the oil system before putting it to actual operation in the craft. Actual test run in the craft is planned for saturday ie. tomorrow! | |||

|

|

||

|

|

||

|

|||